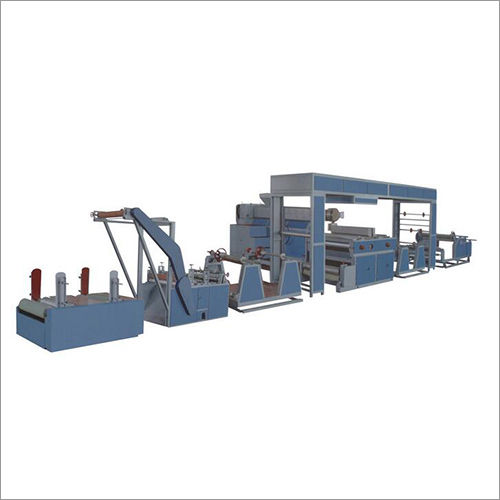

Four Shuttle Circular Loom

Four Shuttle Circular Loom Price And Quantity

- 1 Set

- 2500.00 - 6000.00 USD ($)/Set

Four Shuttle Circular Loom Trade Information

- 50 Set Per Month

- 30 Days

- Yes

- Contact us for information regarding our sample policy

- Western Europe Australia North America South America Middle East Asia Central America Eastern Europe Africa

- All India

Product Description

Designed and engineered using the best tools, our offered Four Shuttle Circular Loom is the best buying product for your textile business. Unmatched in both quality and price, the offered loom has become one of the best selling products of our range. Moreover, it can be customized depending on the specifications of our customers. And, since it is quality checked over several parameters, this is why, our Four Shuttle Circular Loom is highly loved in the Indian market.

Performance and Characteristics

This four-shuttle little cam circular loom is specially designed for the high quality tubular or flat fabric by PP and HDPE. Both the yarn made of 100% recycled yarn and the yarn made of filler master batch up to 40% can be used for weaving low strength and big-sized woven bags; with four-wire motor with 1.5kw, 2.6A can be consumed while weaving. The power consumption is controlled under 200 kilowatt-hour for every 100 thousand meters of fabrics; with inverter speed-regulation, it can meet automatic stops for warp-breaking, weft-breaking and weft ending. The intelligent microcomputer controlling system can be installed, if required. It can adjust the weft density and compensate the weft density in case of weft breaking, which can put an end to the problem of low density and improve the evenness of woven fabrics. Moreover, it can achieve the online remote management, which saves labor intensity and improves business management.

Main technical parameters :

Model | NO. of shuttles (pcs) | Width of weaving (mm) | Max. no of warp (pcs) | Speed of mainframe (r/min) | Capacity (m/min) | Motor power (Kw) | Total power (Kw) | Installing dimension (LxWxH) (mm) | Weight (kg) |

PL-750/4 | 4 | 300-750 | 768 | 140-180 | 1.4-1.8 | 1.5 | 2 | 8300x2200x2700 | 1800 |

PL-1100/4 | 4 | 550-1100 | 896 | 140-180 | 1.2-1.6 | 2.2 | 2.7 | 8900x2400x3000 | 2000 |

PL-1400/4 | 4 | 800-1400 | 1040 | 140-180 | 0.9-1.25 | 3 | 3.5 | 9800x2500x3000 | 2300 |

Note: All technical parameter are subject to change without notice.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese