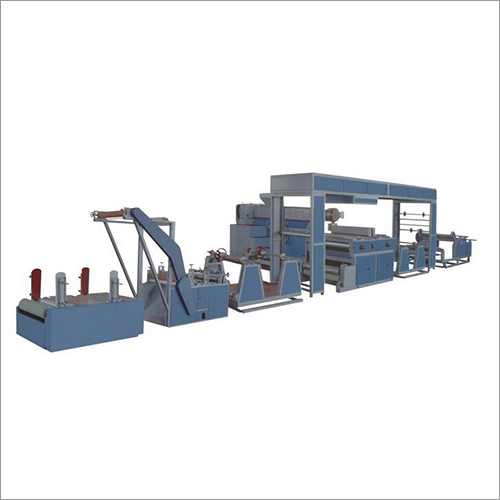

Multifunctional Lamination Machine

Multifunctional Lamination Machine Price And Quantity

- 300000 - 500000 USD ($)/Set

- 1 Set

Multifunctional Lamination Machine Trade Information

- 50 Set Per Month

- 30 Days

- Yes

- Contact us for information regarding our sample policy

- Australia North America Eastern Europe Western Europe Middle East Africa Central America South America Asia

- All India

Product Description

Just as printing, lamination is also important. To help businesses perform the lamination operations without any hassle, we have come up with Multifunctional Lamination Machine that is unparalleled in quality and unbeatable in price. Besides, it is our user-friendly operations for which our our machine is highly demanded not only in the local and National market but International market. If you have a tight budget, then grab the best deals on our offered Multifunctional Lamination Machine.

Performance and Characteristics :

Making use of the good adhesive property of polypropylene & polyethylene at melting status, the machine adheres and laminates paper or color-printed OPP & CPP film to woven bag under pressure, and through cutting-off and sewing to make paper & plastic laminated or color-printed packaging woven bags. It can do coating on woven bags with melted polypropylene & polyethylene film to make laminated woven bag.

The extruder, with helical gear reducer of 20CrMnTi alloy steel and the screw & cylinder made of nitrided 38CrMoAlA alloy steel adopts automatic temperature control system to adjust melting temperature. Width of coating & laminating can be regulated, and step-less speed regulation is to control coating thickness and laminating speed, 6 stations for material feeding. The pneumatic-hydraulic edge correction for rewinder assures the accuracy of coating. Pneumatic roller can assure even pressure. Edge-blowing, edge-correction and winding devices are applied.

Main technical parameters :

Model | Dia. of screw (mm) | L/D ratio of screw | No. of die | Width of die | Gross power (Kw) | Motor power of extruder (Kw) | Max. coating width (mm) | Speed (m/min) | Installing dimension (LxWxH) (mm) | Weight (kg) |

PL-FHJ-1000 | 90 | 28:1 | 2 | 1000 | 71 | 15 | 750 | 50-120 | 14000 x 6000 x 3000 | 8000 |

Note: All technical parameter are subject to change without notice.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese